Test ON FLUID systems

From material testing and component testing to system testing. Our engineers will be happy to help you plan, run and evulate your testing programs with medial load testing in the development and validation process.

Depending on the area of application, the materials and components must be resistant to:

- Liquid or gaseous media

- Temperatures

- Mechanical loads

- Pressure loads

- Vibration loads

As an accredited testing service provider, we test your specimens for strength and operational behavior under the influence of internal and external loads.

Our portfolio

In the automotive sector, we test all subsystems according to OEM specifications, standard specifications or individual load specification requirements. Flexible accreditation by the DAkkS enables us to test components or materials according to different specifications/standards.

Test of tanks AND TANK systems

Car, truck, motorcycle, quad or boat: the tank system of every vehicle is subject to the highest safety regulations. Strict legal testing standards therefore apply in accordance with defined specifications or individual requirements.

Testing methods

- Fuel permeation on tank systems according to GS 97014 (SHED test)

- Pressure / Vacuum test

- Pressure cycling stress

- Slosh test on the vehicle tank system (starting and stopping)

- Vibration test

- Leak tests, e.g. with helium

- System ventilation and extraction

Testing media

- Air, helium, hydrogen -1 to 300 bar rel.

- Fuels (gasoline, diesel and alternative)

- Liquid coolants

- Lubricants (different oils)

- Special media (e.g. Urea/AdBlue®)

TEST ON FLUID SYSTEMS

In our test laboratory, we test the load-bearing capacity of your products under real and extreme conditions in accordance with generally recognized standards or individual load specification requirements.

From the fuel system to the interior and the exhaust system: the operational reliability of entire components and assemblies is based on the functional behavior of individual lines or complex subsystems.

Test methods

- Pressure / Vacuum test

- Pressure cycling

- Vibration test

- Leak tests, e.g. with helium

- System ventilation and extraction

- Temperature cycling

Test media

- Air, helium, hydrogen -1 to 300 bar rel.

- Fuels (gasoline, diesel and alternative)

- Liquid coolants

- Lubricants (different oils)

Tests of fluid technology

In our high-performance laboratories, we determine the behavior of your test specimen under the loads of pressures, volume flows, temperatures and mechanical loads. Regardless of whether this involves individual lines, components, units (pressure generators, pressure consumers) or complete systems with the use of special media according to your specifications.

Test methods

- Leak tightness with positive or negative pressure

- Internal high pressure test of fuel-carrying systems

- Leak test using total pressure change methods (Group D-DIN EN 13184)

- Flow measurement

- Pressure swell test

- Burst pressure test

- Motion simulation

- Vibration test

- Temperature control

- Functional test

- Test of chemical resistance according to current automotive or aviation standards

Test media

- Air, helium, hydrogen -1 to 300 bar rel.

- Fuels (gasoline, diesel and alternative)

- Liquid coolants

- Lubricants (different oils)

- Special media (e.g. Urea/AdBlue®)

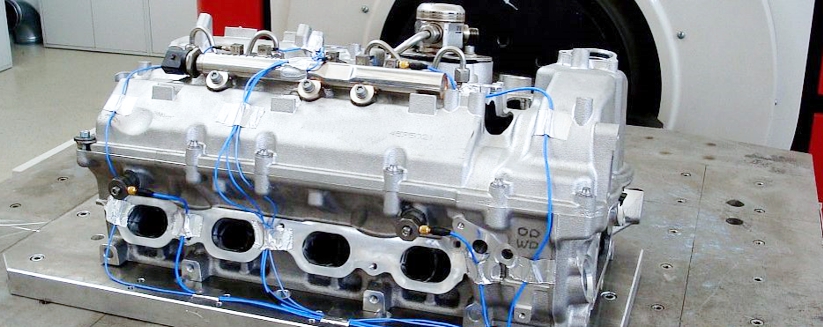

PRESSURE Pulse Test

We can execute pressure impulse testing, leak tests, burst pressure tests on hydraulic components, pipework, fittings, fittings, fuel lines, injection systems and rails. This enables the pressure pulse strength to be tested with indoor dynamic tests. Combining pressure pulse tests and vibration tests in accordance with IACS and DNVGL Type Approval also enables hydraulic fittings to be tested for bending with loads for internal pressure.

Certification tests for hydraulic systems are just one part of our testing spectrum as well as comprehensive validation inspections e.g. for fuel rails.

Testing spectrum

- Pressure impulse testing

- Hydro pulse tests

- Combined pressure pulse testing and vibration testing (IACS, DNVGL)

- Bursting pressure test

- Leakage tests with various media (oil, water, nitrogen, helium among others)

- Pull-Out-Test

- Vacuum testing

Test Standards (selection)

| IACS Req. 2006 | International Association of Classification Societies | Requirements concerning pipes and ressure vessels P2.11 Type Approval of Mechanical Joints |

| GL | Germanischer Lloyd | Classification Provisions and Construction Provisions for Pipework Fittings |

| DNV | Det Norske Veritas | Standards for Certification No. 2.9 Type Approval Programm No. 5-792.20 Pipe Couplings |

| BS 4368 Part 4 | British Standard | Compression Couplings for Tubes |

| ISO 19879 | International Organisation for Standardisation | Test procedure for metallic pipe fittings utilising fluid Technology |

| ISO 6605 | International Organisation for Standardisation | Hydraulic fluid power. Hoses and hose assemblies. Test methods |

Test parameters

| Pressure, dynamical | Dynamic maximum pressure up to 1,400 bar Typical pulse frequency 1 Hz Up to 30 Hz sinusoidal |

| Vibration | Bending frequency of hydraulic pipes or tubes up to 20Hz |

| Curve shapes | Sine, triangle, trapezoidal or standardised curves e.g. according to IACS P2.11.5.5.3, among other things, DNVGL |

| Temperature | Ambient temperature -40°C up to 140°C |

| Pressure, static | Burst pressure testing up to 4,000 bar |